ASFOUR-FS® | Outside Plant Copper Cable (Exchange Cable) | Aluminum Steel Shield | Single Jacket | Filled Foam Skin

Pair Count 6 – 3000P

ASFOUR-FS® (Telecom Copper Cables | Aluminum Steel Shield | Filled Foam Skin)

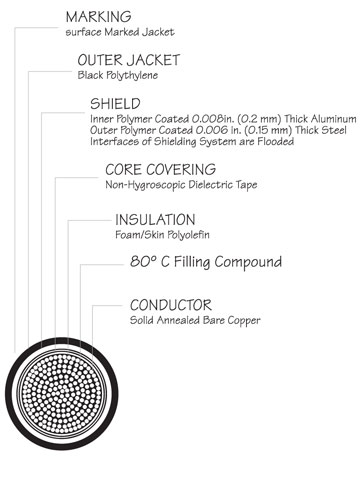

Conductors: Solid annealed copper in 19, 22, 24 and 26 AWG.

Insulation: Conductors are dual insulated with an inner layer of foam, natural polyolefin covered by an outer layer of solid, colored polyolefin. The conductor insulation is color-coded in accordance with industry standard.

Twisted Pair: Individual conductors are twisted into pairs with varying lay lengths to minimize crosstalk and specific color combinations to provide pair identification.

Core Assembly: Cables of 25 pairs or less are assembled into a cylindrical core. Cables larger than 25 pairs are assembled into units, which are then used to assemble the core. Units are individually identifiable by color-coded unit binders.

Filling Compound: The core assembly is filled with an 80° C ETPR or PIB base jelly compound, completely filling the interstices between the pairs and under the core wrap.

Core Wrap: A non-hygroscopic, dielectric tape is applied over the core assembly to provide protection for the core.

Shielding: The dual shielding system consists of two metal tapes. Inner: A corrugated, copolymer coated, 8-mil aluminum tape is applied directly over the core wrap. The aluminum tape does not butt or overlap at any point along the length of the cable. Outer: A corrugated, copolymer coated, 6-mil steel tape is applied directly over the aluminum and overlaps. The shield interfaces are flooded with an adhesive compound to provide a moisture barrier and inhibit corrosion.

Jacket: A black, linear low-density polyethylene jacket is applied overall. The jacket provides a tough protective covering designed to withstand exposure to direct sunlight, atmospheric temperature changes, and stresses expected in standard installations.

Jacket Markings: Information, such as manufacturer’s identification, pair count, AWG, product identification and a telephone handset is printed at 2 ft. intervals on the cable jacket. Sequential footage markings are printed at alternate 2 ft. intervals.

Optional Designs: AsFOUR®-FS is available with an internal screen for use with T-Carrier systems. AsFOUR®- FS is also available with mechanical protection.

4S is a global leader in the wire and cable industry with more 40+ years of experience in manufacturing Low, Medium & High Voltage Energy Cables, Fiber Optic Cables, Aluminum Conductors and Telecom Copper Cables.

Sales & Technical Support

4621 Ponce de Leon Blvd.

Coral Gables, FL 33146 - USA

+1 305.666.7474

+1 305.666.7272 (Fax)

sales@4sproducts.com

technical@4sproducts.com

support@4sproducts.com